Die Kreise schließen!

The economy and the environment must complement each other!

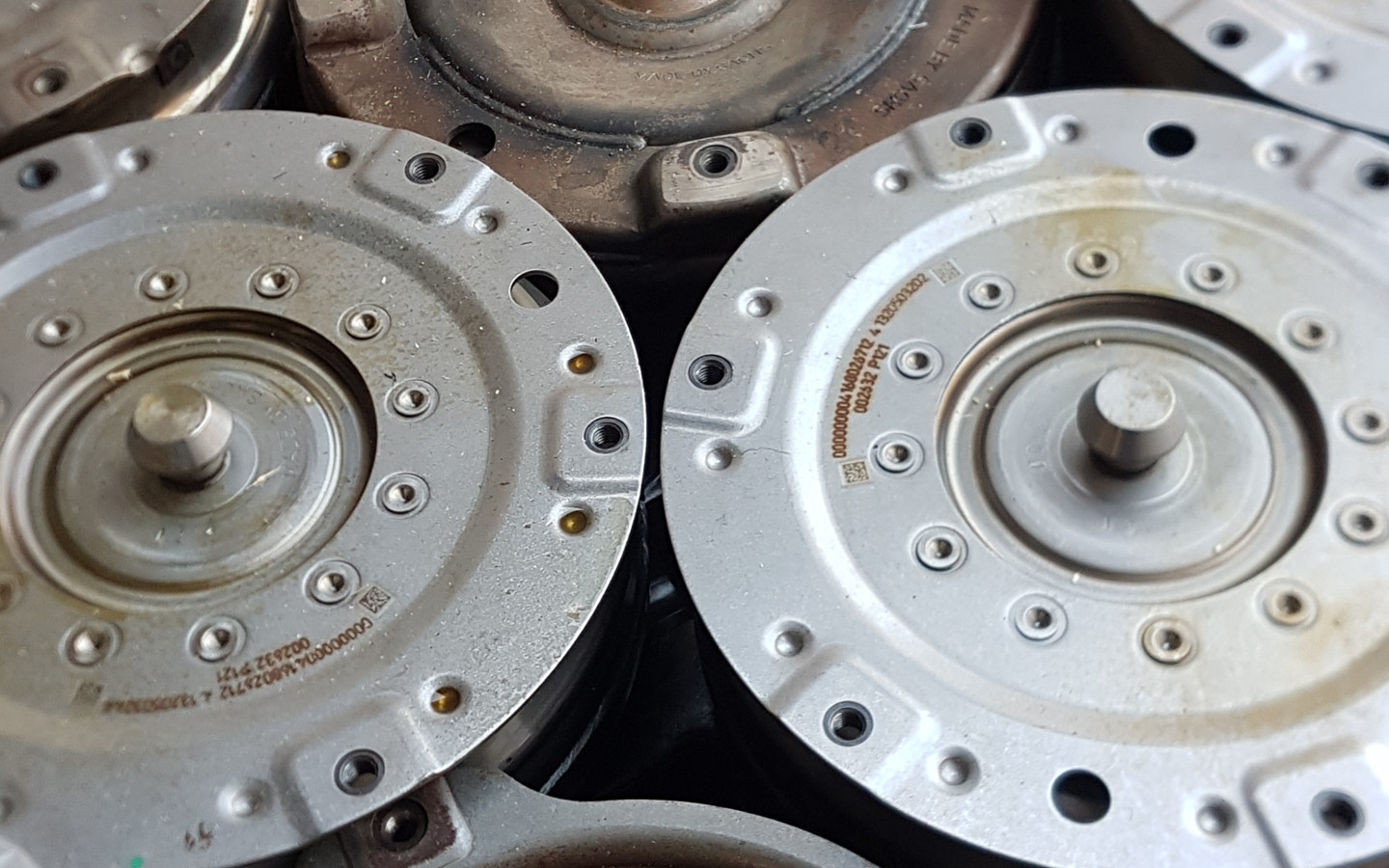

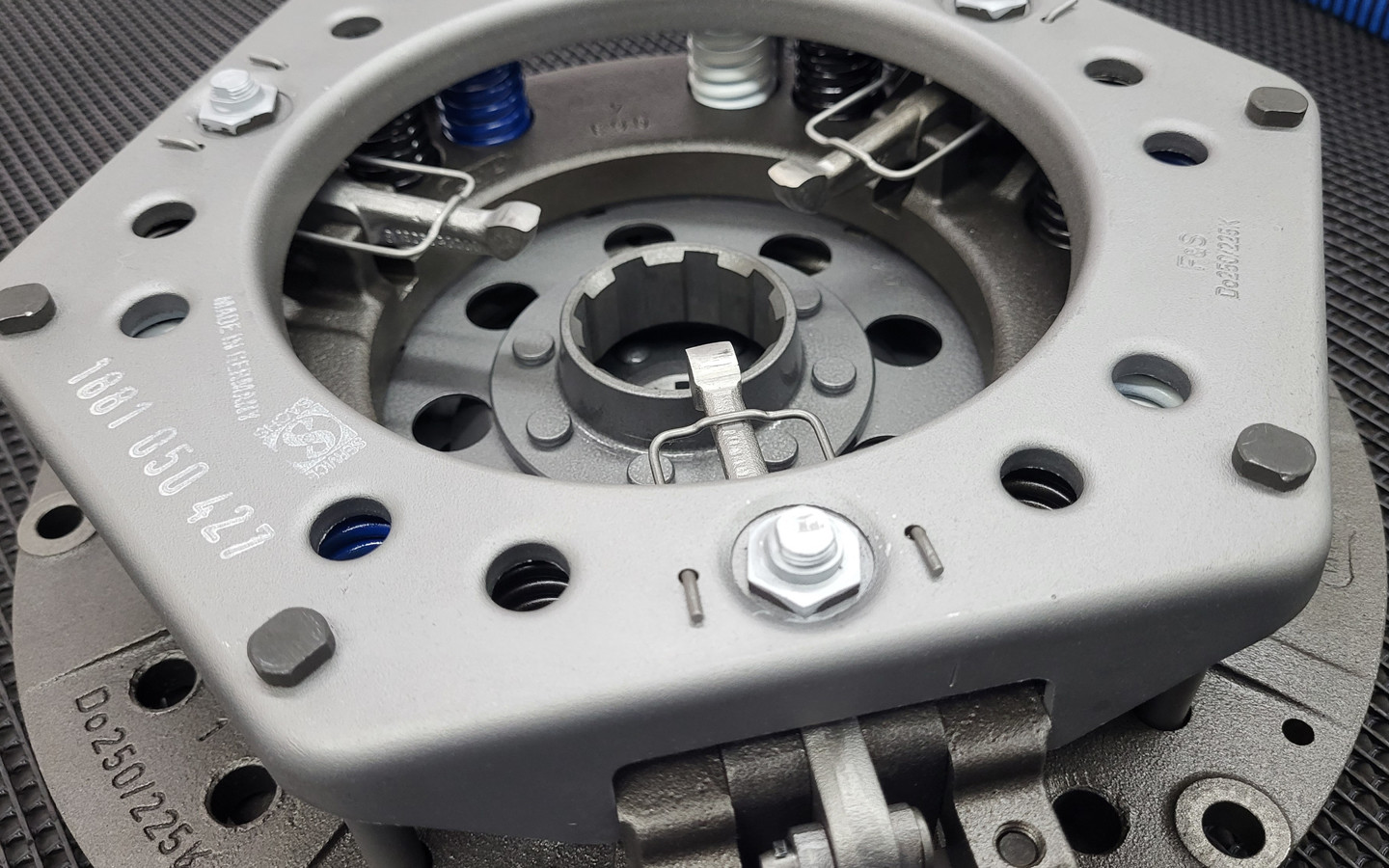

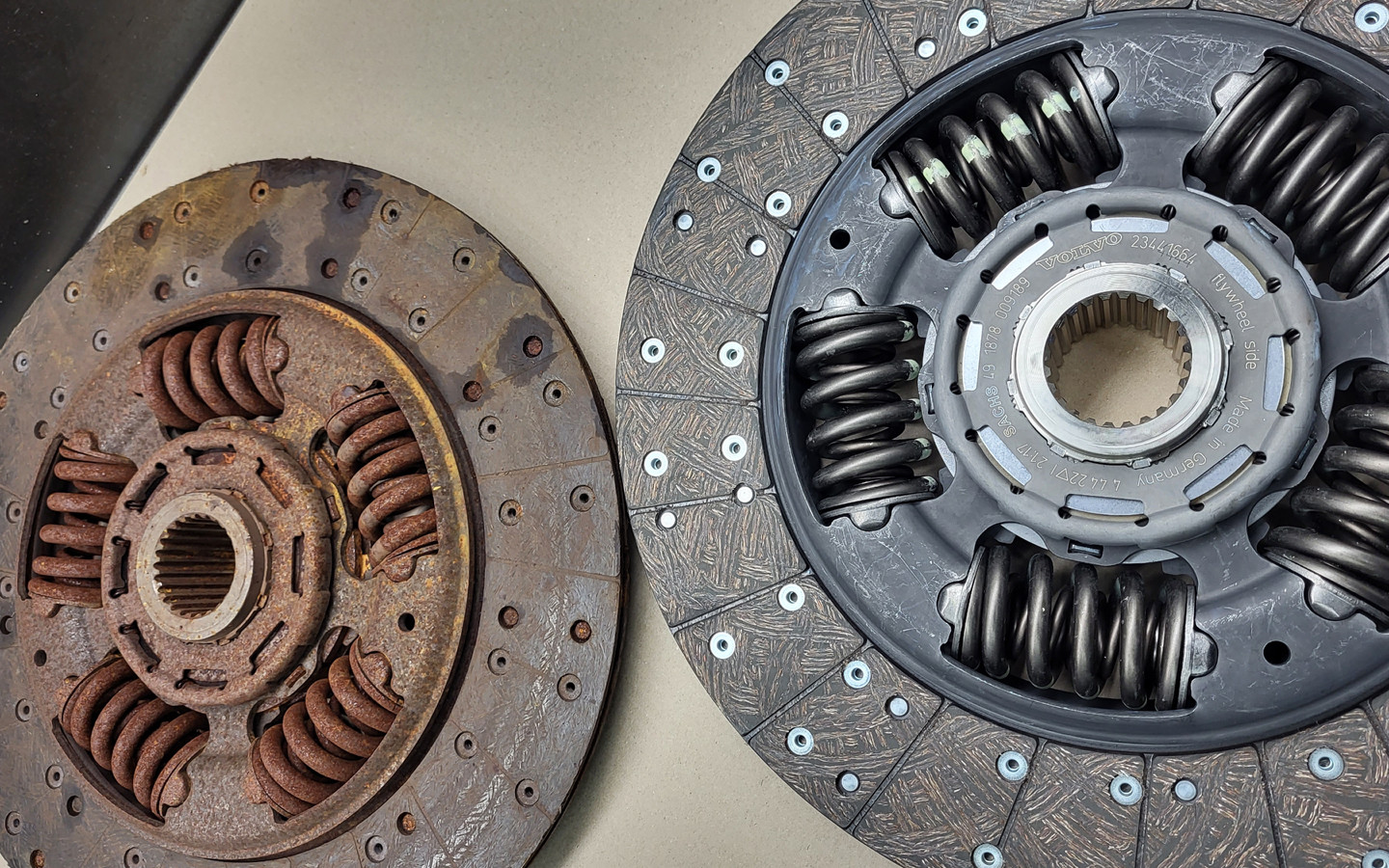

ZF Bielefeld remanufactures used vehicle parts (clutches, etc.) for the aftermarket, following Cradle to Cradle (C2C) principles. This process reduces material usage by 50-90% and energy consumption by up to 90% compared to new parts, supporting a circular economy. The company uses human expertise, is developing return software and AI for quality control, and aims to increase its returns of old products to 90% by 2028. All products are C2C certified.

Company/Institution

ZF Friedrichshafen AG, Werk Bielefeld

Am ZF-Standort in Bielefeld lebt von der Kreislaufwirtschaft. Der Betrieb ausgediente Kupplungs-Altteile von Nutzfahrzeugen zurück, arbeitet sie auf und haucht ihnen frisches Leben wieder ein. So finden ca. 180.000 Kupplungen und Kupplungsscheiben, 8.000 Drehmomentwandler und 50.000 Ausrücksysteme als Fertigprodukte mit gleichem Qualitätsstandard wieder den Weg in den Markt. Das Altteilegewicht jährlich entspricht das Gewicht des Eiffelturms. Auf diesem Wege sparen wir nicht nur Ressourcen, sondern auch Energie ein. Die 17 SDG’s der UN hängen in Bielefeld aus und stehen im Mittelpunkt.

Country

Germany

Designer(s)

Standortleiter Herr Witthöft

Unser Standort in Bielefeld ist durch ihn zu einem Vorzeigestandort für Nachhaltigkeit geworden, schon bevor es bei der ZF eine Nachhaltigkeitsabteilung gab. Er hat Eigenverantwortlich dafür gesorgt, dass wir einen C2C-Standart haben. Seine Aktivitäten dafür gehen über seine tägliche Arbeitszeit sehr weit hinaus. Auch soziale Aktivitäten wie z.B. der Lions-Club oder Vorträge in der Freizeit sind für ihn ein Ansporn die Umwelt und die Wirtschaft zu verknüpfen.